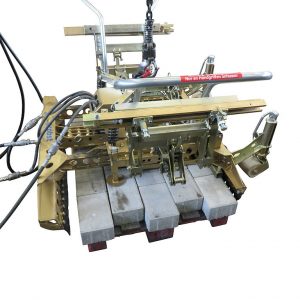

POWERPLAN PP Screeding Machine

Standard Aspalt Paving Machines, (Finisher) are working with scratch converyors and worm shafts to distribute the material. Wen screeding sand or schipping for the bedding of concrete-pavers, this abrasive material is wearing away these components very fast, which is causing high maintenaunce costs.

On the one hand, the POWERPLAN PP Screeding Machine was specially designed to transport and screed sub-base and base materials as well as bedding materials such as sand or chipping without any major wear on the machine parts.On the other hand screeding this material for being underneath concrete pavers requires different working prodedures than to screed asphalt. For example it is sometimes necessary overlap tracks, to screed an area twice etc.

The result is now a unique and innovative machine to combine transportation of material and screed the material at the same time, delivering a perfect screed at the right level, without major wear on the machine. Enormous daily rates of up to 10,000 sqm (11,959,9 sqft) are achievable.

PP:

- Dead Weight kg (lbs): 2.500 (5,500)

- Payload kg (lbs): 3.500 (7,700)

- Power (kW): 18,5

Product description

Standard Specifications:

- Quick filling of the hopper reservoir with a wheel loader shovel upt to 2,500 mm (98″) wide, from the front or sideways.

- Hydraulic liftable front cute, in order to allow charging also with small loaders, enormous important for working inside underground car parks.

- Sideways foldable chutes to avoid that material is spilling over the side of the hopper and thus requiring manual rescreeding.

- Two independently hydraulically operated lids at the bottom of the hopper to perfectly control the material flow. Important to be able to screed narrow strips or overlapping tracks.

- Basic width of the screed booard 2,050 mm (81″). By using one board extension on either side extendable to 2,400 mm (94″) or even 2,850 mm (108″).

- On either side one smoothening board can be fixed to extend the full working width to 3,450 mm (136″).

- Simple operation by well arranged instruments. 2 working lights throw light on the area between the outlet lids and the screeding board. Most important for working in underground car parks or during night shifts.

- Smooth-running adjustable cantilevers for holding the sonic sensors (sonic ski) complete scanning width up to 6,500 mm (256″). So a 6,000 mm (236″) wide road can be screeded scaning from kerb to kerb.

- Compact transportation measurements HxBxL 1,900×2,050×3,400 mm (75″x81″x134″) can be transorted on a car trailers.

Height control system optional via:

- Sonic sensors (sonic ski)

- Laser sensors

- Inclination sensors

Accessories:

- Foldeable and detachable sun/rain roof for the operator, Laser Set, Remolte Control, Telescopic Leveling Post, Tripod.

Reviews

There are no reviews yet.